In the past year, café owners across the country have reassessed the environmental impacts of their processes and products. For many, this has involved buying organic coffee, or a change in paper cup manufacturer or the way leftover coffee grounds are collected. But what about the packaging materials used to sell wholesale bags of beans?

“For companies that want to embody a completely sustainable ethos and reduce their carbon footprint in their operations with a clear environmental conscience, we believe Goglio’s new plant-based bio-laminate is the best way. To our knowledge, it’s the only offering of its kind on the market,” says Jet Technologies’ General Manager Daniel Malki.

Unlike paper coffee cups, which are lightweight and hold a small volume of liquid, Daniel says producing a biolaminate coffee bag to withstand large volumes and weights is no easy feat.

“Coffee bags are complex barriers. When designing this new material, Goglio had two main considerations: they needed to produce a bag that was functional but also sustainable,” Daniel says.

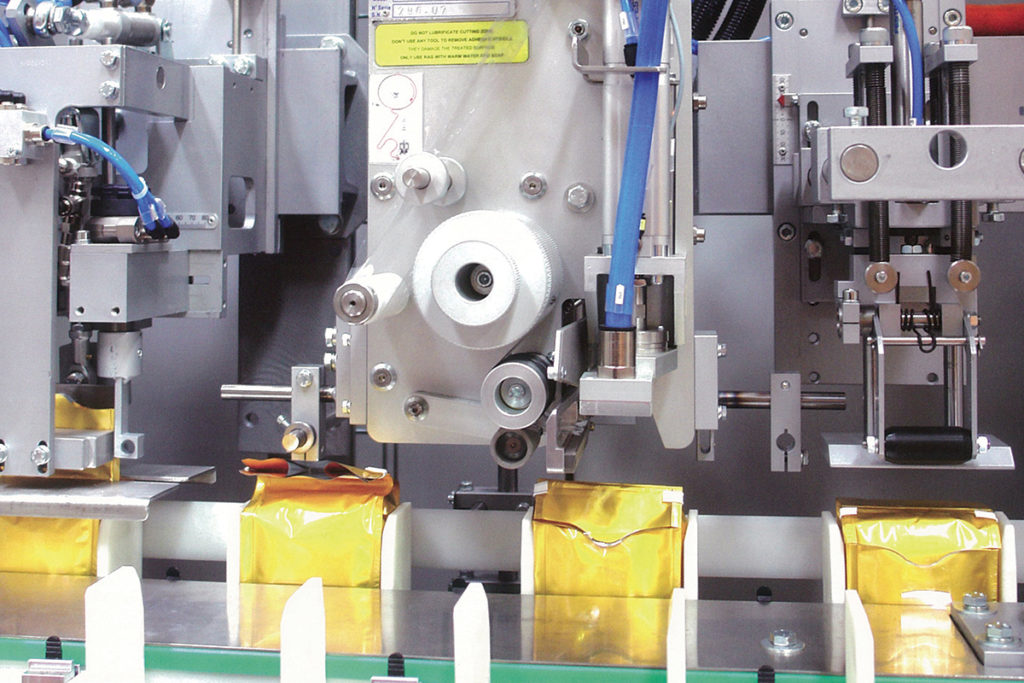

Jet Technologies had been looking for a fully bio-laminate material for its coffee bags for a long time. The criteria were strict. Daniel says the product range had to retain a long shelf life so cafés wouldn’t be pressured to use the coffee immediately. He also wanted a laminate that was robust to withstand the fast pace of packaging machines and transporation, and strong enough to hold large volumes of coffee beans. The material also had to be puncture resistant, easily pulled a part fast to break down efficiently, and one that looked good. With all that in mind, Italian packaging manufacturer Goglio set to work with its designers and engineers to create a product that ticked all the boxes.

What it came up with was a paper-based laminate with a polylactic acid (PLA) film. The PLA is made of renewable raw materials such as cornstarch or sugarcane, and is printed with bioinks.

Just like a bag of chips you would find from a vending machine, Daniel says most packets feature an aluminium coating on the inside layer – a thin coating of about five to six-micron deposits of aluminium ‘metalisation’ that acts as an oxygen barrier. Goglio’s packaging features a new technology called Alox, a high-barrier, transparent packaging material.

“We needed a material that would break down, could be recycled, and look beautiful, and we’ve found the best of all worlds,” Daniel says. “This Goglio technology is at the leading edge of packaging materials and allows consumers to see what the product is while retaining the oxygen properties of the product, which in this case is coffee.”

The company is behind its patented one-way degassing valve that allows carbon dioxide – which is naturally emitted by the roasted coffee – to be released from the packaging, excluding air to enter the atmosphere. This little plastic addition has helped maintain coffee freshness since the 1950s, and now, the Italian company is set to tackle its coffee bag packaging head on with its commitment to sustainable packing options.

“As a leading packaging company, we like to bring new innovations from Europe to Australia, which is why we’re so pleased to be the first in the country to offer this bio-laminate. One of our core values is to have a strong environmental conscience and deliver that message to customers,” Daniel says.

The material passed biodegradability standards and the “drop test”, which as the name suggests, is a test of strength where the bag is dropped with the weight of beans.

In order for a product to be defined biodegradable and compostable, the Board of Certification has to certify the product by Vinçotte in Europe. To gain this certification, 95 per cent of the total mass of certified materials has to be manufactured using compostable raw materials. Each must be compliant with four essential law requirements: quantity of heavy metals, biodegradability, disintegration, and ecotoxicity.

According to regulations, half of the material components must be volatile (organic) and exclude inert materials, and reach a biodegradation level of at least 90 per cent during a 180-day period.

To test the bio-laminate’s disintegration, once disposed of as compost, it was placed in an aerobic environment. After 12 weeks the residual mass of the test material showed to be less than 10 per cent of the original dry mass. The material was also placed in an anaerobic condition and left for five weeks. The residual mass of test material showed to be less than 10 per cent of the original dry mass. Lastly, the material was tested for ecotoxicity – a test of germination speed and vegetal biomass as compost and as decomposed matter.

Inks used on packaging are generally made of non-compostable materials, but under the strict Vinçotte ruling, in order to be biodegradable the inks used on the Goglio bio-laminate had to fall within the 1 to 5 per cent range of non-bio components of the pack. The outcome was a packaging material made from paper, laminated with PLA film, and printed with bioinks.

Daniel says the level of testing in Europe is a reassurance for buyers that the product will be a welcome environmental addition. Once sent to local councils for processing, the PLA will break down on its own, and the paper can be extracted and recycled, depending on the council’s processing abilities.

The product will be available in Australia and New Zealand from February 2018, exclusively from Jet Technologies.

“We’re excited to show the market of café owners and roasters. Compared to 10 years ago, Australian consumers want to know more about the product they’re using: what it’s made of, where it’s from, how safe it is to use, and its environmental impact,” Daniel says. “They have a social conscience, and with this new laminate product, consumers can confidently say they’re doing everything they can to be environmentally friendly right across the board.”

Daniel says he understands this new bio-laminate material has to meet commercial needs and it is an investment, but says the product only speaks to what the market wants.

“We’re under the belief there’s a demand for environmentally friendly products, and we think the profile of roasters is in line with our strong environmental conscience too,” Daniel says. “I’m proud to be part of the Australian coffee industry and providing a new product we believe can make a big impact.”

For more information, visit www.jet-ap.com

This article features in the February 2018 edition of BeanScene Magazine. Subscribe here today www.beanscenemag.com.au/subscribe