Packaging is often a customer’s opening interaction with a brand, and McIver’s Tea and Coffee is partnering with Trimatt to take back control of that crucial first impression.

Packaging is the customer engagement king. It’s the first impression a potential consumer has of a brand, and the quality of what’s in the bag bears no weight if the bag itself doesn’t draw attention.

In a bustling space like Melbourne’s Queen Victoria Market, where busy food and beverage traders vie for the business of locals and tourists alike, the ability to craft an intriguing brand proposition and capture a potential customer’s interest is integral to success.

McIver’s Tea and Coffee has been trading at the Market since 1972 and has grown to operate an additional site in Brunswick. Initially, McIver’s sold health foods, supplements, and tea and coffee. In the early 2000s, it pivoted to focus solely on tea and coffee.

“We switched from a multi-pronged approach to just tea and coffee. Nobody was really into tea at that point, so we pretty heavily pushed into that. Caffeine customers are a cheerful bunch,” says McIver’s Owner Catherine Underhill.

“We don’t roast our coffee ourselves; we have a primary roaster and then two other roasters we work with. Our current primary roaster told me his father could smell coffee in a hessian sack and know what it would taste like when it’s roasted. I realised I would never be able to do that, but we’re great at the retail side.

“We source most of our tea though, and blend all but three of them ourselves. We’re really putting a lot of effort into finding indigenous, reliable sources and making blends from that.”

Recently, McIver’s elected to bring its packaging potential back into its own hands. After previously relying on bulk-orders and a manual labelling system for its tea packaging, the business purchased a Trimatt ColourStar AQ LT to bring those elements in-house – and to great success.

Now, the need to hold large, cumbersome volumes of pre-printed stock has been eliminated and the business has greater control and agility in its packaging production process.

“Having the Trimatt in-house removes the need to have up to 50,000 versions of each colourway lying around. Space is always at a premium, no matter how much you have you’re always going to fill it up. We could do a bulk order for 50,000 units of one bag and work our way through it in a few months, but where would we put the other 200,000 for our other products?” says Catherine.

“Now, we can just get blank bags, redesign them when we want to, and print runs of 100 bags at a time.

“We sell tea by the kilogram and offer bulk options too, which limits our packaging needs. Therefore, to be able to print our bags in smaller runs as we need them is both a space and cost saver.”

The ColourStar AQ LT is the entry-level model of Trimatt’s ColourStar package printing range. It is targeted at businesses with a limited product portfolio that still desire the agility and flexibility that comes with being able to print their own packaging.

The digital printing solution has adjustable product handling and a five-millimetre print head height adjust, as well as a ‘full bleed’ feature for those that require edge-to-edge packaging printing and want to eliminate white borders.

It uses organic pigment, waterproof, light-fast, and scratch-resistant inks that can print on paper, cardboard, and even cotton, and measures a compact 1580-millimetres wide by 800-millimetres deep. It also offers on-demand CMYK digital printing for short runs.

Catherine says the ability to print in-house with the ColourStar AQ LT has given McIver’s the ability to create a unique look and feel for each of its tea products while saving time in-store. In fact, she says the whole process has been a “liberating” experience.

“We have 70 different teas, so we can now easily create unique packaging for all of those in a fraction of the time it would take otherwise,” she says.

“We’re currently in a switch-over process, so it’s amazing to be able to try something or even make really simple changes to the packaging such as altering the volume or origin. You don’t only end up with bags all in one colour, but you also don’t end up with three pages of labels that might have the wrong information on them.

“We print what we’re going to pack, so we don’t have overruns. It’s quite liberating to be able to go at it gently rather than needing to dive in and change everything all at once and have one decision impact thousands of bags.”

Since McIver’s has implemented the ColourStar AQ LT into its operations, not only has labelling, storing, and packing product become a faster and less labour-intensive process, but the creation of excess waste that would otherwise be bound for landfill has been limited.

Catherine says the added dimension of sustainability has long been important to McIver’s.

“We used to get six different versions of bags printed and then have to label them afterwards, and that was really messy and incredibly time consuming. We didn’t have a bag labeller, so we were doing that by hand. Given the size of the business, it was possible but not ideal,” she says.

“Using the Trimatt means we’re not using labels as well as bags. We’re very dedicated to the fact when we sell our tea, it comes in just the one bag. It’s not boxes inside other boxes, all of which is then wrapped in cellophane.

“We’ve worked on being as environmentally friendly as possible for a long time. We’ve been offering 50 cents off for customers who reuse their container since about 2003, and we do our best to offer a high-quality product at a reasonable price.”

Catherine says Trimatt’s customer service potential was also a key driver in McIvers’ selection of the ColourStar AQ LT and that support in operation of the machine is only a phone call away should she need it.

“In the end, we were tossing up between Trimatt and another company, but we elected to go with Trimatt because the interface was easier to operate. It came with the computer, the software, and everything you need to get started, plus the software gets updated as needed,” she says.

“It’s a very rounded operation. There were other companies overseas and in Australia who we were initially considering, but that ability to pick up the phone if something goes wrong is so important.

“We’ve only had one issue we needed to get in touch with Trimatt about. Not only was it very minor but it was also solved incredibly quickly and effectively by the team.”

With the continuing rise of online shopping, the stresses that can come with maintaining physical storefronts, and the ongoing pressures on the coffee industry, streamlining operations where possible in any business could be the difference between success and stagnation.

Adding that agility and efficiency has, according to Catherine, been helped by the addition of the ColourStar AQ LT.

“In what we do, there’s always change. The coffee business right now is definitely in a state of flux,” she says “Even though we like being eminently brandable and scalable, I like the fact we’re at a level where we can send our product all around Australia and do good business but also retain the positive aspects of still being small.

“In the long run, bringing packaging in-house with the ColourStar AQ LT has saved us time and labour, made us more agile, and helped add another layer of professionalism to our product as opposed to it looking more like a workshop operation.”

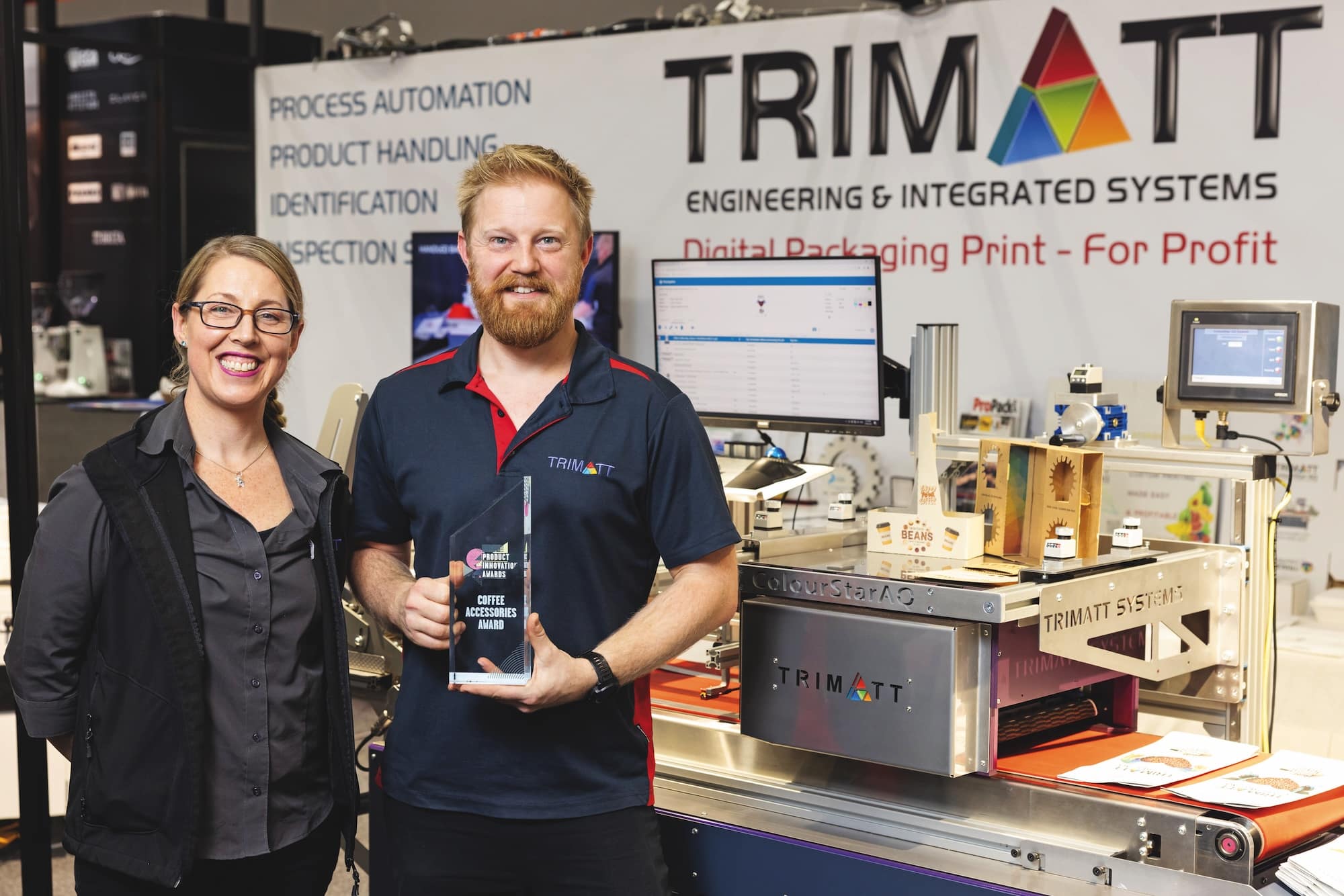

Trimatt will showcase a larger version of the ColourStar AQ LT – the ColourStar AQ V – at Fine Food Sydney in September 2025 for tea and coffee roasters interested in a live demonstration.

For more information, visit trimatt.com

This article appears in the August 2025 edition of BeanScene. Subscribe HERE.